cGMP Cell Banking

ATUM’s cGMP-compliant Cell Banking Facility provides full assurance of uninterrupted operation, and of the quality, of manufactured master cell banks (MCB) and working cell banks (WCB). ATUM offers cell banking from CHO cell lines developed in-house or elsewhere, along with molecular, viability and growth potential testing of cell banks in storage stability programs.

SPEED TO IND

ATUM’s end-to-end process from DNA design to MCB release provides the materials, traceability and analytics to fully support your IND filing.

SPEED TO MANUFACTURING

ATUM’s integrated process enables you to compress your timelines and get to manufacturing faster without taking risky shortcuts.

Cell Banking

Productivity and product quality from stable pools made using our Leap-In Transposase® technology is representative of the derivative clones, enabling earlier initiation of process, analytical, and pre-formulation development, and manufacturing of material for toxicology studies. This accelerated timeline brings the selection of the final clone and the decision on MCB manufacturing significantly closer.

During cell line development, the final clone’s growth and cryopreservation characteristics are established, and the cell culture media is selected. A simple, unhindered internal tech transfer into our cell banking facility is an attractive alternative to time-consuming tech transfer between different CROs. We offer cell banking scheduling priority to our cell line development clients, further shortening the CMC timeline.

Compliance

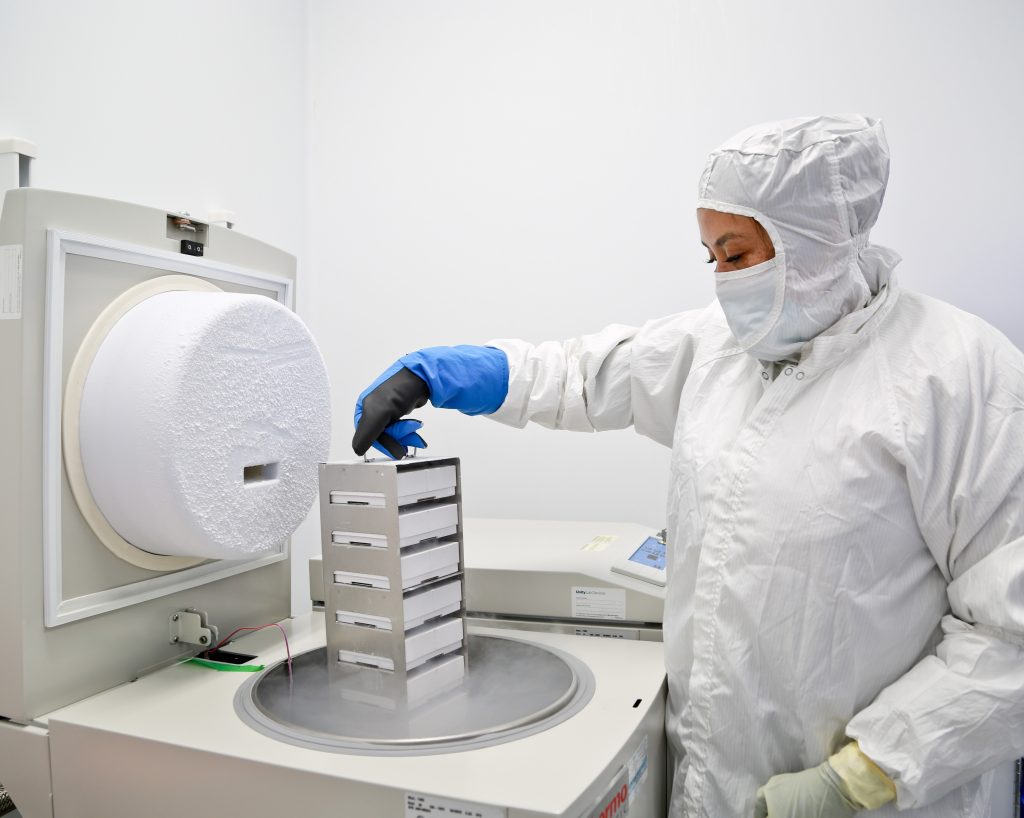

ATUM’s cell banking facility comprises a dedicated ISO7-classified manufacturing suite with multiple qualified ISO5-classified working spaces and ISO7- and ISO8-classified supporting rooms with controlled access.

We follow the guidelines in 21CFR Parts 210 and 211/1271, ISO 14644-1, ICH Q5D and ICH Q7.

QA / QC

We operate an animal origin-free and antibiotic-free facility, utilizing single-use, disposable technology. All QA released raw materials are stored within the cGMP compliant facility. The cell banking facility is maintained and operated in accordance with ATUM’s Quality Systems, including:

- Qualified and certified, redundant HVAC units to maintain the required air changes and differential pressure.

- Qualified and maintained backup generator.

- Constant monitoring of qualified laboratory equipment by a validated monitoring alarm system.

- Routine environmental monitoring of ISO 7 and ISO 8 cleanroom suites.

- Preventative maintenance and calibration programs for all qualified equipment.

- Temperature-mapped controlled-rate freezer for optimal cryopreservation of cell banks in standard or 2D barcoded cryovials.

Cell Banking testing and storage

- We perform molecular characterization (cDNA sequencing), viability at thaw and growth potential assessments prior to cell bank release to client or for storage.

- Purity and safety testing performed by our qualified partner laboratories.

- Qualified temperature-mapped autofill storage units provide onsite short-term storage in vapor-phase liquid nitrogen in a controlled access suite. Cell banks are divided between storage units.